Sieve Analysis Test Report

CONSTRUCTION REPORT 1: SIEVE ANALYSIS

(CONSTRUCTION LAB)

Introduction:

The

objective of this experiment consists in determining the particle size distribution of

fine and coarse aggregates to find soil properties by a soil analysis. We use

12 sieves of different diameters, a brush, a balance, and soil.

Description

of the apparatus:

Experimental procedures:

1) Use the

brush to clean all the sieves.

2) Determine

the mass of each sieve without soil.

3) Place the

sieves with openings of decreasing size from top to bottom (a pan is placed

below the stack).

4) Determine the mass of soil sample = the mass of (soil+ sieve) – the mass of sieve.

5) The soil then is shaken through the stack of sieves

Theoretical

basis:

1) Determine

the total mass of the soil: M1 + M2 · · · +Mn + Mp = M

2) Determine

the cumulative mass of soil retained above each sieve. For the I’th sieve, it

is M1 +M2 +. · · + Mi

3) The mass

of soil passing the I’th sieve is M = (M1 + M2 +· · · +Mi)

4) The

percent of soil passing the I’th sieve (or percent finer) is F= [ M-( M1+ M2 +….

+Mi)] *100/M

5) The

calculations are finally plotted on semi-logarithmic graph paper

Data

collection and calculation:

Mass of soil

sample = 1052g

|

Sieve opening (mm) |

Mass of sieve (g) |

Mass of soil + sieve

(g) |

Mass of soil retained

(g) |

Cumulative mass

retained (g) |

%Retained |

%Passing |

|

50 |

612 |

612 |

0 |

0 |

0 |

100 |

|

37.5 |

556.5 |

556.5 |

0 |

0 |

0 |

100 |

|

25.4 |

577.5 |

595 |

17.5 |

17.5 |

0.37 |

99.63 |

|

25 |

559.5 |

571 |

11.5 |

29 |

0.58 |

99.42 |

|

12.5 |

602.5 |

2171 |

1568.5 |

1597.5 |

31.95 |

68.05 |

|

4.75 |

575 |

2197 |

1622 |

3219.5 |

64.39 |

35.61 |

|

2 |

534 |

616 |

61.5 |

3281 |

65.62 |

34.38 |

|

1.18 |

493 |

535 |

42 |

3323 |

66.46 |

33.54 |

|

0.85 |

487 |

538 |

51 |

3374 |

67.48 |

32.52 |

|

0.425 |

452 |

873 |

421 |

3795 |

75.9 |

24.1 |

|

0.15 |

424.5 |

1500 |

1075.5 |

4871.5 |

77.43 |

22.57 |

|

0.075 |

415.5 |

522 |

106.5 |

4977 |

99.54 |

0.46 |

|

pan |

468.5 |

491 |

22.5 |

4999.5 |

99.99 |

0.01 |

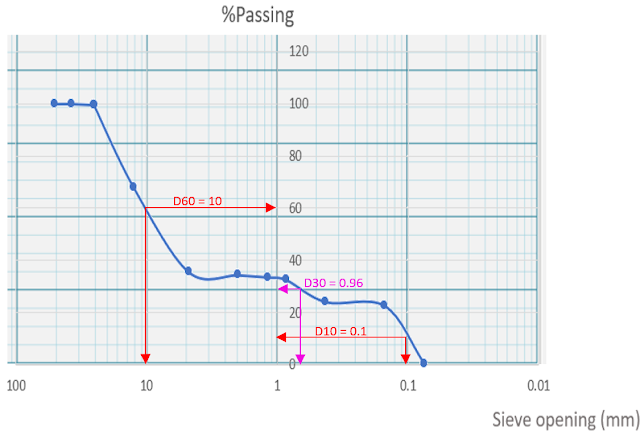

Draw the graph using log 10 scale for the x axis:

Uniformity coefficient: Cu = D60 / D10 = 10/0.1 = 100

Coefficient of gradation: Cc = (D30) ^2 / (D60*D10) = 0.96^2/ (10*0.1) = 0.9216

Sorting coefficient: S0 = (D75/ D25) ^0.5 = (42 / 0.92) ^0.5 = 6.756

At last, the soil is classified using the following rules:

- If Cu < 2: uniform graded soil

- If Cu > 4 and Cc is in between 1

and 3: well-graded gravel else poorly graded or gap graded gravel

- If Cu > 6 and Cc is in between 1 and 3: well-graded sand else poorly graded sand.

This measure tends to be used more by geologists than

engineers. The larger So, the more well−graded the soil.

For well−graded soils, Cc~ 1.

Soils with C u <= 4 are considered to be "poorly graded" or uniform.

The "effective size" of the soil: D10.

Empirically, D10 has been strongly correlated with the permeability of fine−grained sandy soils.

References:

1) Construction

lab (BAU)

2) Book: principles of geotechnical

engineering (25th edition)

The information in the post you posted here is useful because it contains some of the best information available. Thanks for sharing it. Keep up the good work. pls visit our website Christopher Contracting.

ReplyDeleteThanks!

Delete